Welding Course (2023)

In this two day welding course at George Brown College, I learned manual arc welding, metal inert gas (MIG) welding, brazing, and plasma cutting.

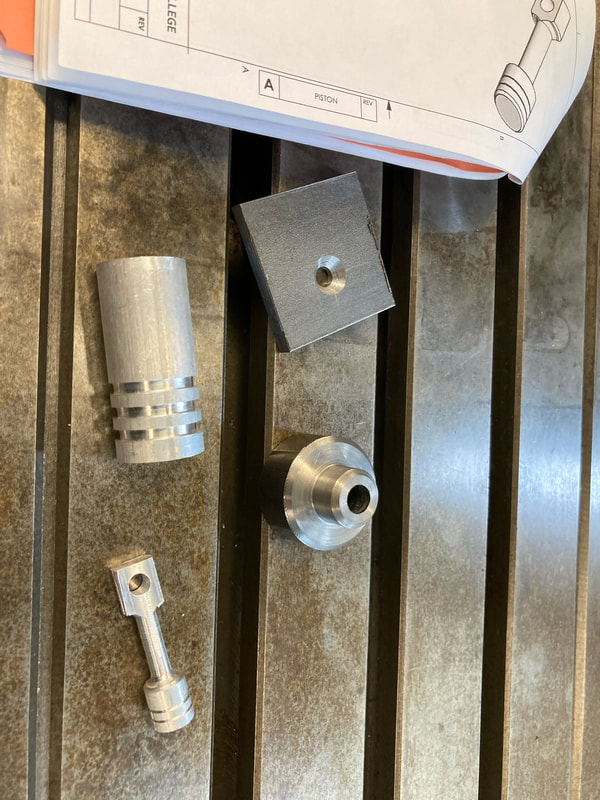

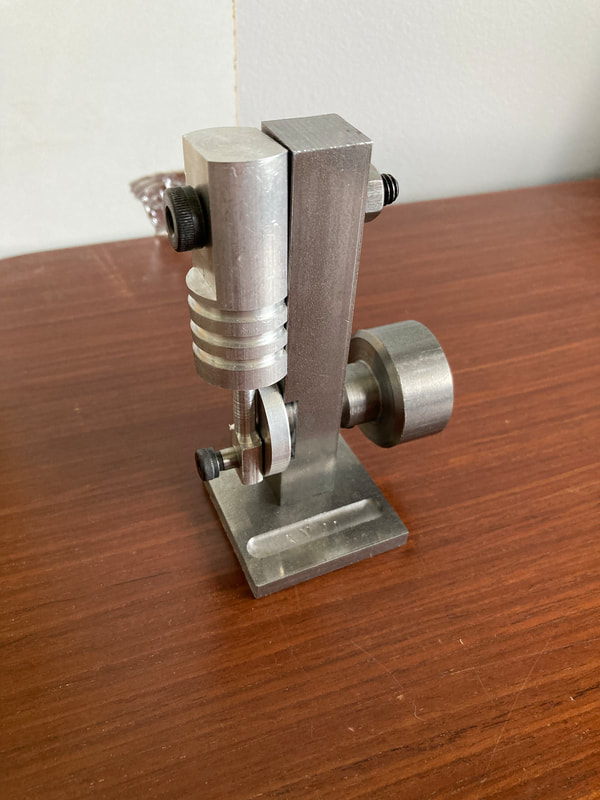

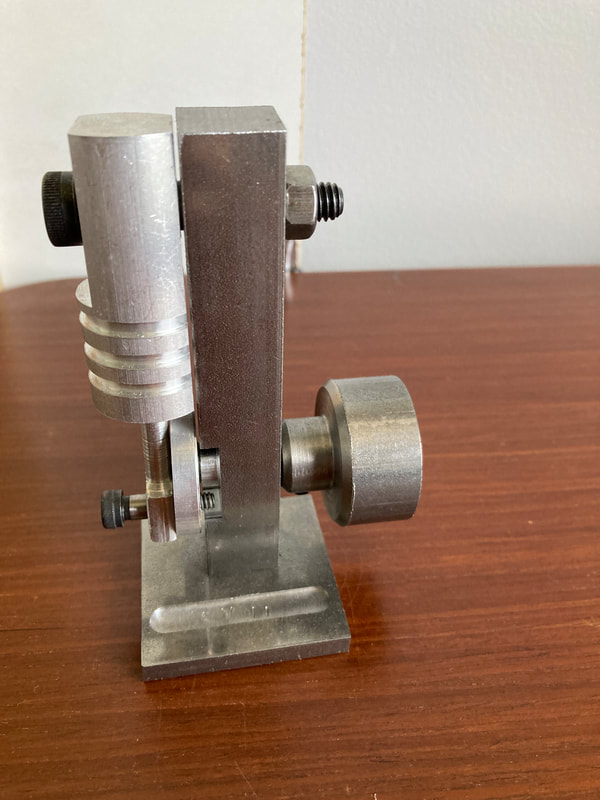

Pneumatic Engine (2022)

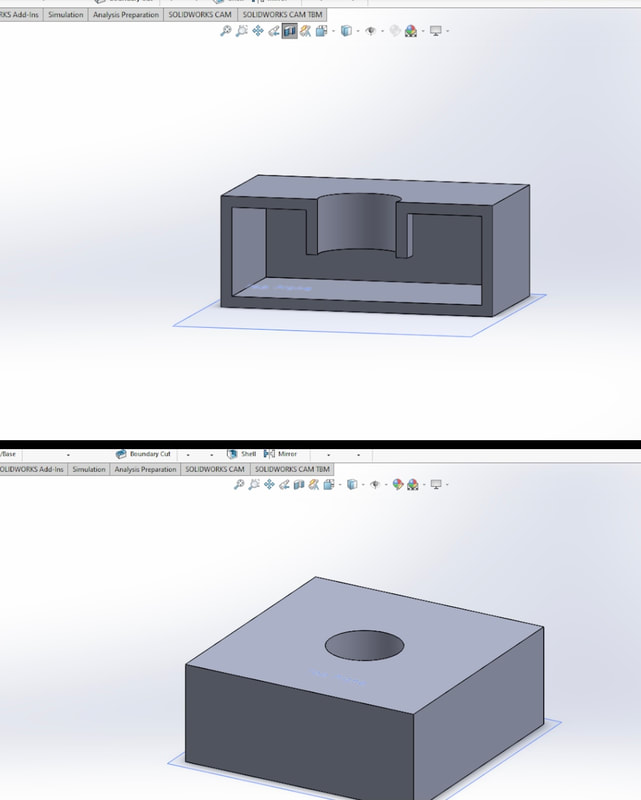

In this two day machining course at George Brown College, I learned to safely operate a lathe, 5-axis mill, drill press, and reamer. We machined four of the parts (the cylinder, piston, flywheel, and base), and then assembled it into an engine. One thing I found very interesting is that the engine uses a slider crank mechanism. We had learned about the slider crank mechanism in my mechanical design course, but it was lovely to see it being used in a simple but real application.

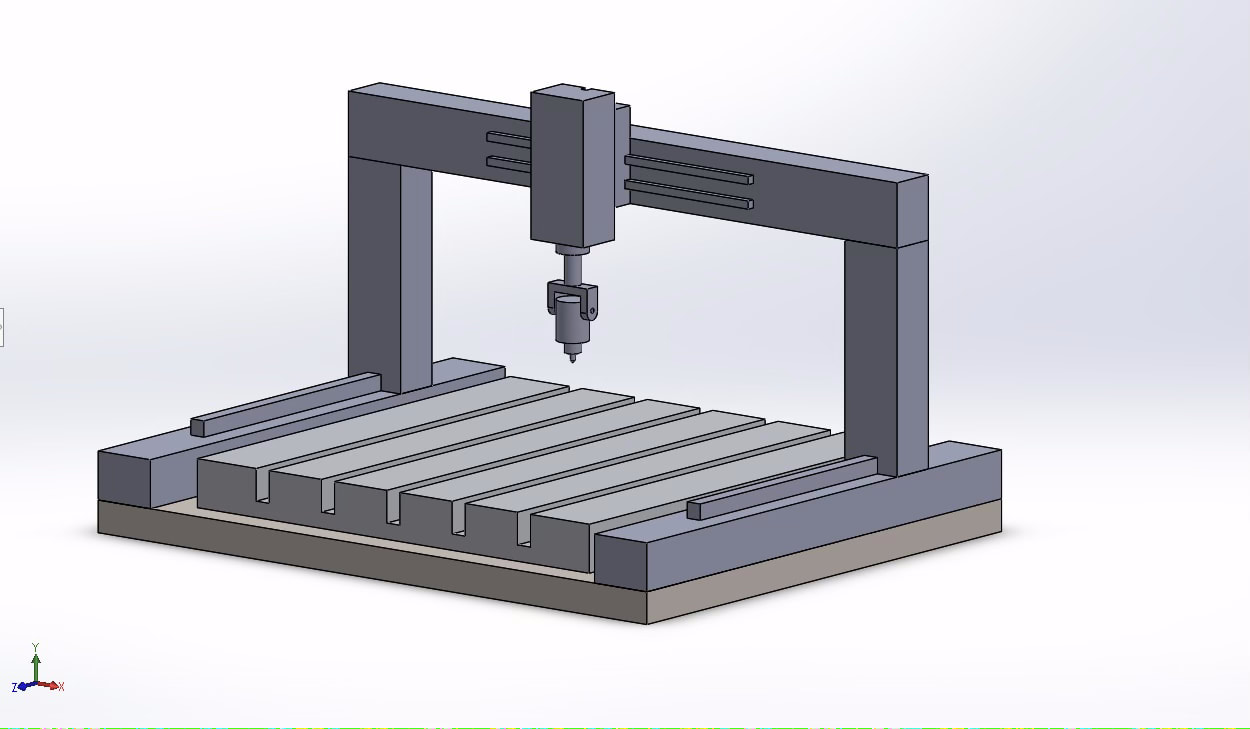

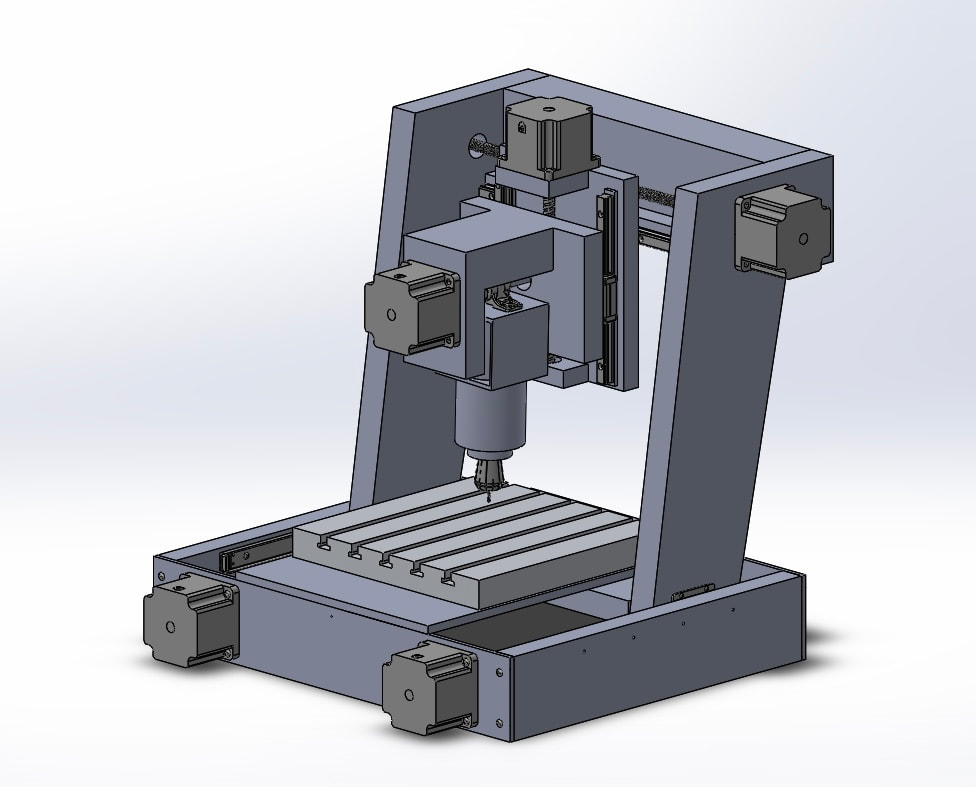

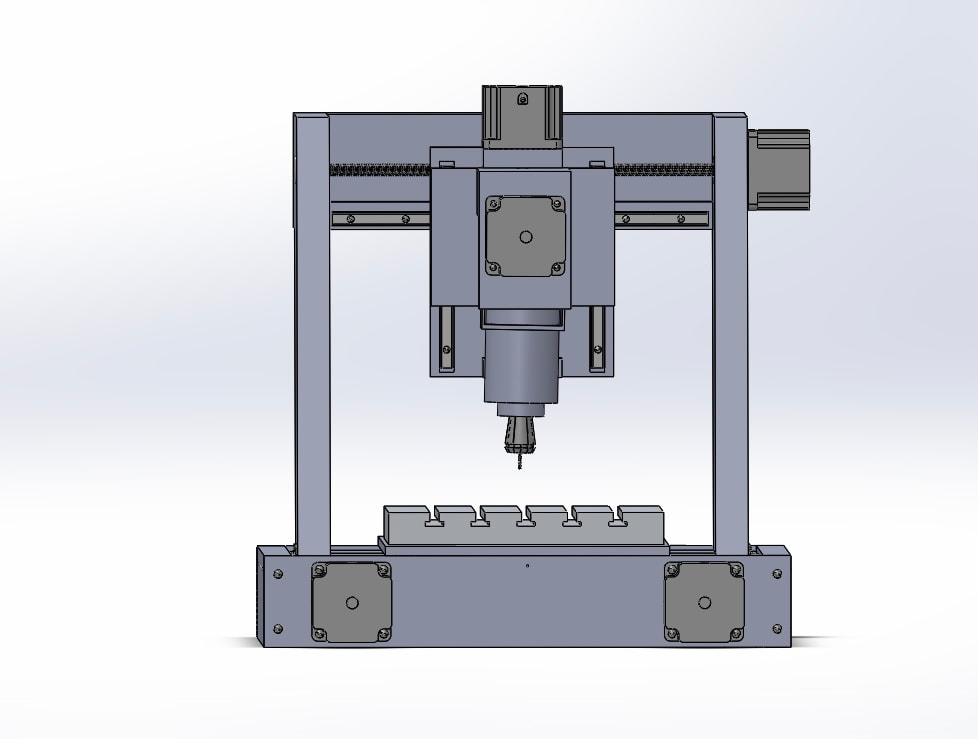

4-Axis CNC Milling Machine (2021)

In our Mechanical Engineering Design course (MIE243), we researched CNC milling machines, and designed one for a specific purpose. Our team designed a CNC machine that is targeted towards biomedical applications; it is meant primarily "for rapid prototyping of personalized tools and implants based on surgeon and patient requests." [1]

We first researched current CNC machines on the market to gain an understanding of how they work, and then began designing our own. We created three candidate designs and then narrowed down which design best suited the intended application. When designing this machine we applied the knowledge we gained from the lectures. For example, we used two lead screws and a ball screw for linear motion, and we used our knowledge in CAD to create a final design.

[1] A. Tilva, T. De Freitas, E. M. Ortiz, G. Povolo, "4-Axis CNC Milling Machine for the Biomedical Industry," University of Toronto, 8-Dec-2021.

We first researched current CNC machines on the market to gain an understanding of how they work, and then began designing our own. We created three candidate designs and then narrowed down which design best suited the intended application. When designing this machine we applied the knowledge we gained from the lectures. For example, we used two lead screws and a ball screw for linear motion, and we used our knowledge in CAD to create a final design.

[1] A. Tilva, T. De Freitas, E. M. Ortiz, G. Povolo, "4-Axis CNC Milling Machine for the Biomedical Industry," University of Toronto, 8-Dec-2021.

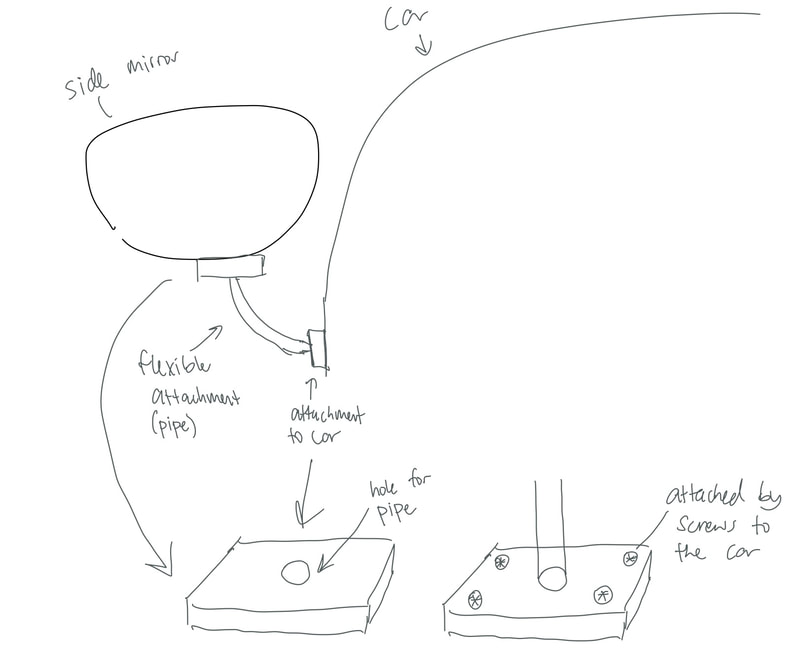

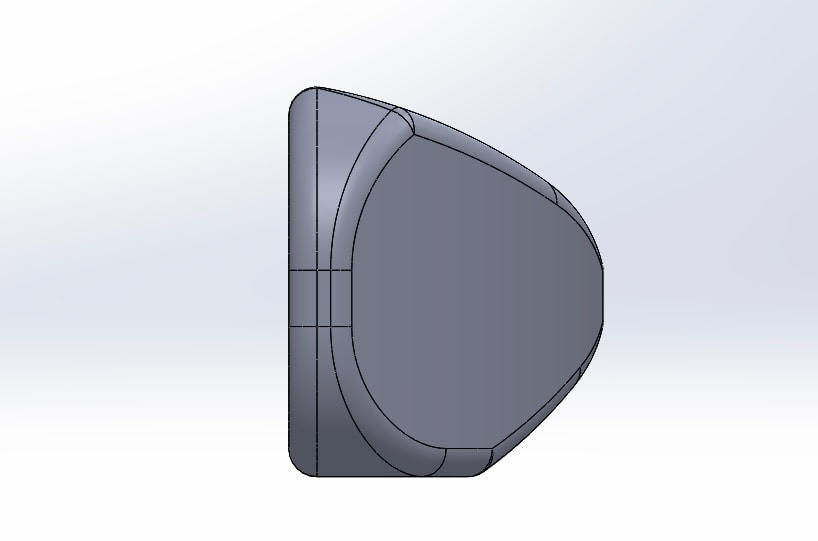

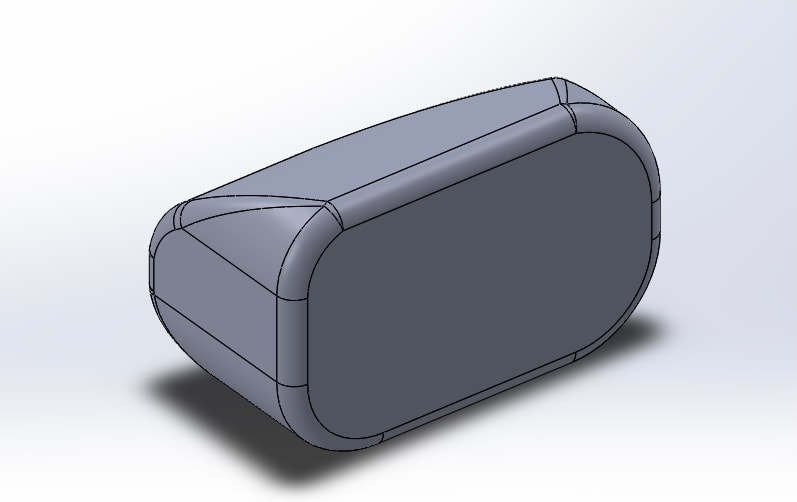

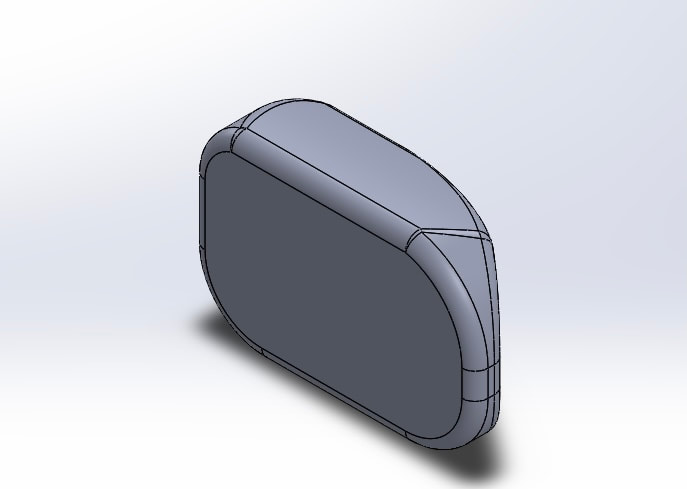

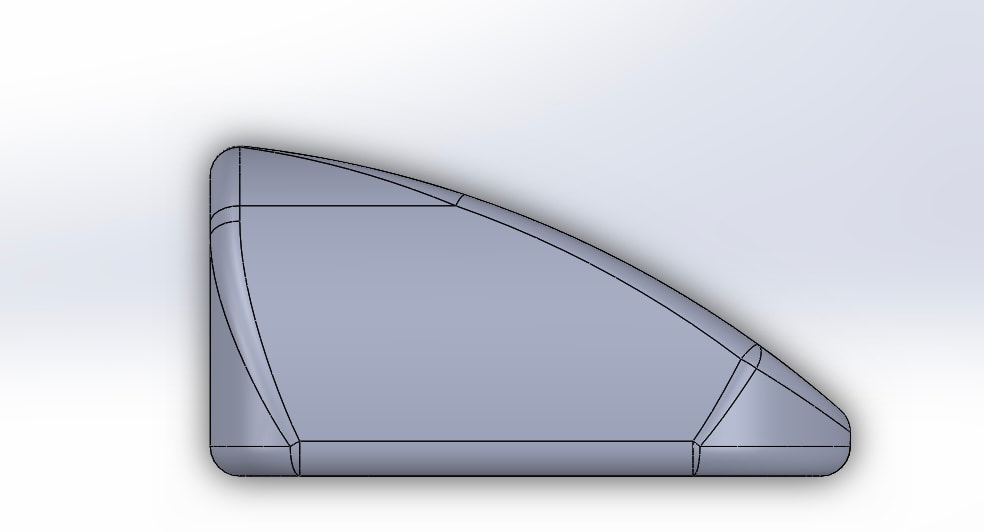

UTSM Urban Concept Side Mirrors (2021)

The side mirrors for the UTSM Urban Concept Team. The objective was to create lightweight mirrors, with a surface area of 2500 square mm.

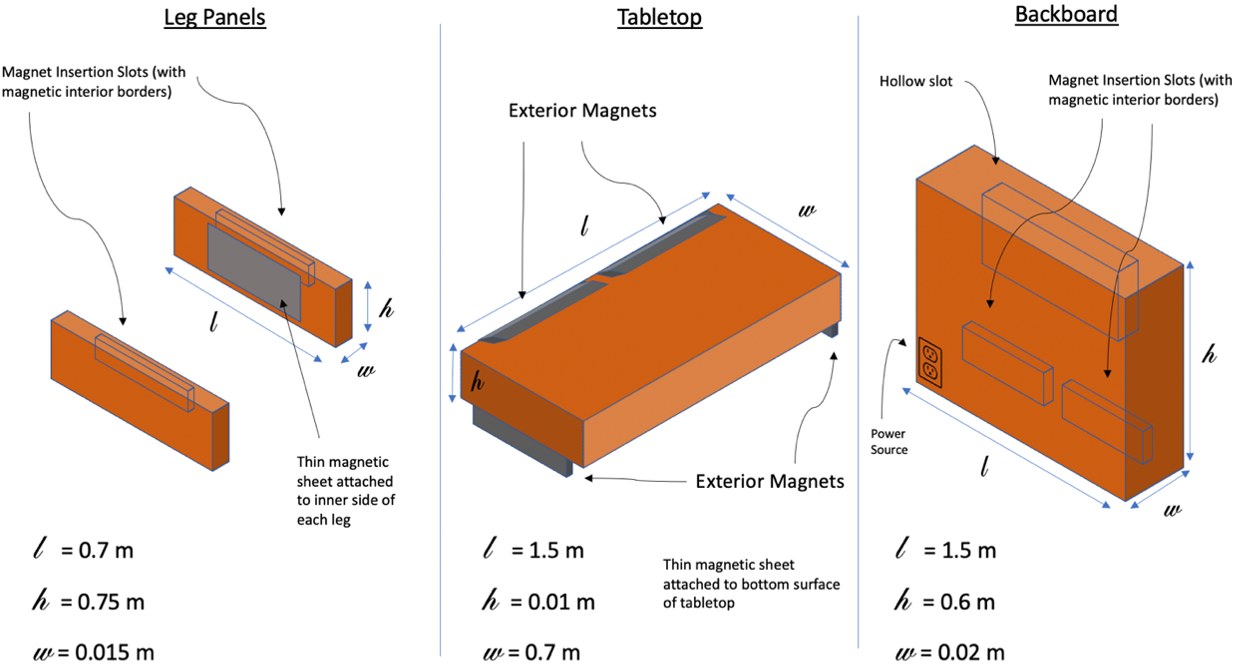

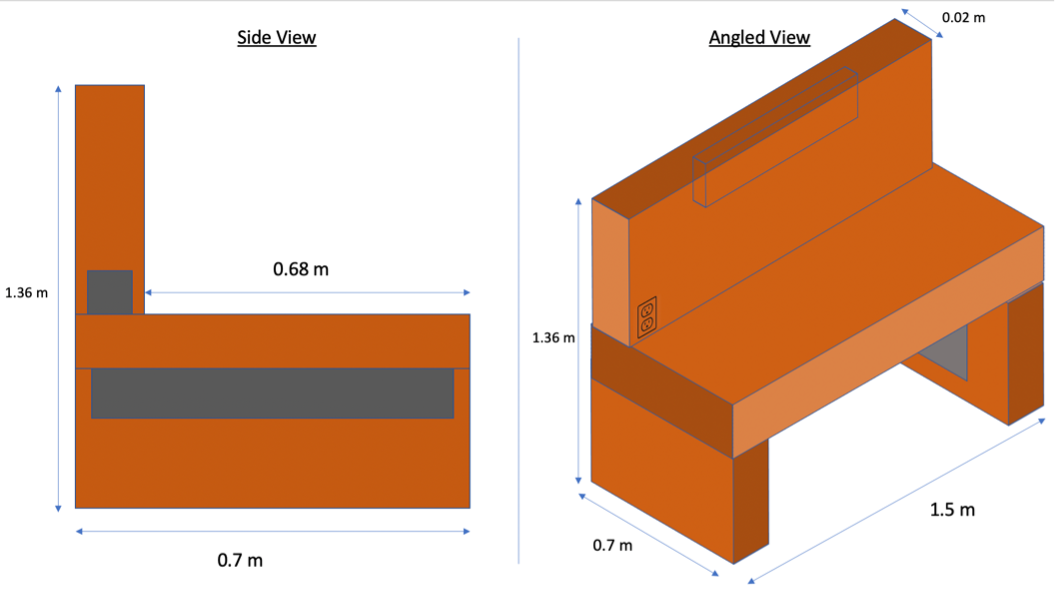

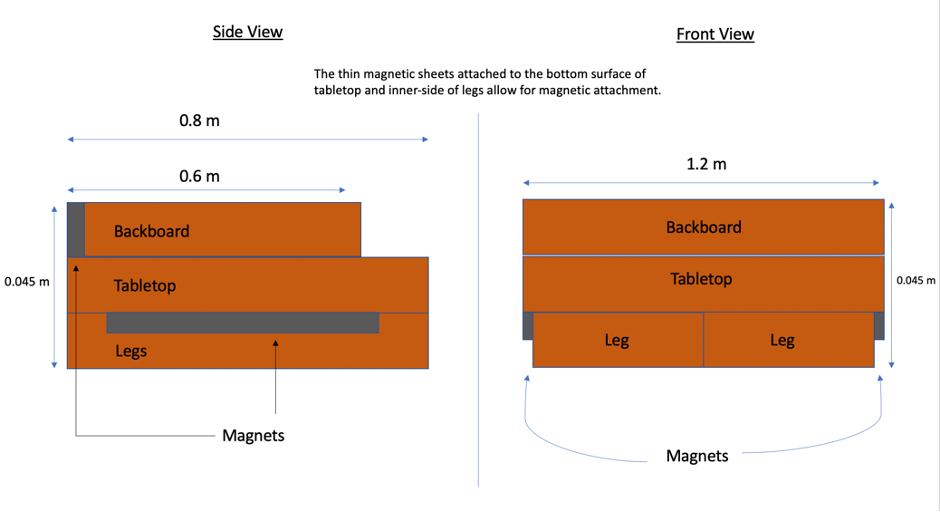

Piecewise Magnet Workbench (2021)

In our Engineering Strategies and Practices course (APS112), my team and I were tasked with creating a conceptual design for a portable workbench for a client. The objective of this project was to create a lightweight and portable workspace that our client could use for creating his personal mechanical and electrical projects in a small space.

After lots of brainstorming, creating many candidate designs, and going through multiple iterations of our final chosen design, we created the 'Piecewise Magnet Workbench.' We believe this design to be a possible solution to our client's problem. It was designed specifically for our client's needs, and it uses magnets to create an easily foldable and portable workbench.

Note: I did not create the following images, another team member did.

[2] S. Kim, N. D. Valle, R. Ahmed, A. Jain, A. Tilva, J. Satsoruban, "Portable workbench in small apartments for 'DIY' projects," University of Toronto, 5-April-2021.

After lots of brainstorming, creating many candidate designs, and going through multiple iterations of our final chosen design, we created the 'Piecewise Magnet Workbench.' We believe this design to be a possible solution to our client's problem. It was designed specifically for our client's needs, and it uses magnets to create an easily foldable and portable workbench.

Note: I did not create the following images, another team member did.

[2] S. Kim, N. D. Valle, R. Ahmed, A. Jain, A. Tilva, J. Satsoruban, "Portable workbench in small apartments for 'DIY' projects," University of Toronto, 5-April-2021.

Copyright © 2023 Avni Tilva